One of Hottest for Diesel Filter Assembly - Diesel Engine Fuel Water Separator Filter 1311812 FS19554 BF7672D RE62421 131-1812 For Truck Engine – MILESTONE

One of Hottest for Diesel Filter Assembly - Diesel Engine Fuel Water Separator Filter 1311812 FS19554 BF7672D RE62421 131-1812 For Truck Engine – MILESTONE Detail:

Product Size

Outer diameter: 83mm

Outer diameter 1: 69mm

Height: 154mm

Cross reference OEM NO

CATERPILLAR: 131-1812

BALDWIN: BF7672-D

DONALDSON: P550503

FLEETGUARD: FS19554

FLEETGUARD: FS19839

HENGST FILTER: H291WK

LUBERFINER: L 8681F

MANN-FILTER: WK 8110

PZL SEDZISZOW: PDS724

WIX FILTERS: 33638

Management and maintenance

Before using the fuel-water separator, the turbine operation and management personnel should understand the start-up, operation and maintenance requirements of the separator according to the product’s use and maintenance instructions.

一: Start-up inspection and preparation

1: Obtain the approval of the bridge before using the fuel-water separator equipment to discharge

2: Check the line installation of the fuel-water separator and whether the steering of the supporting pump is normal

3: Supply water to the oil-water separator and open the top air valve to allow air to escape

4: Check that there is no leakage on the water inlet and outlet systems of the fuel-water separator

2: Precautions during operation

1: Adjust the valve opening of the drain line to maintain pressure in the separator to facilitate the removal of dirty oil in the separator

2: Observe whether the pressure gauge, temperature gauge and other indicating instruments are normal

3: Observe the working conditions of the treated drainage water quality and oil concentration alarm

4: After the discharge is over, you should continue to inject clean water and run for 15 minutes to clean the separator

5: After stopping the pump, close the inlet and outlet valves to avoid the loss of clean water in the cylinder and reduce the oxidation and corrosion of the inner wall

6: Every time the oil-water separator is used to discharge, it should be recorded in the oil record book

Three: maintenance

1: Regularly clean the filter, open the release valve at the bottom of the separator, and remove the sediment and impurities deposited in the lower part

2: Clean the internal separation components of the separator in time, and do not use cleaning agents to clean the inner wall and components of the separator

3: When there is a failure, the cause should be found out and the failed coalescing element should be replaced in time

Four: internal anti-corrosion

Contact us

(Exported company of Hebei Bossa Group CO., LTD)

Cell: 86-13230991855

Skype:info6@milestonea.com

Whatsapp: 008613230991855

www.milestonea.com

Address: Xingtai High-tech Development Zone, Hebei . China

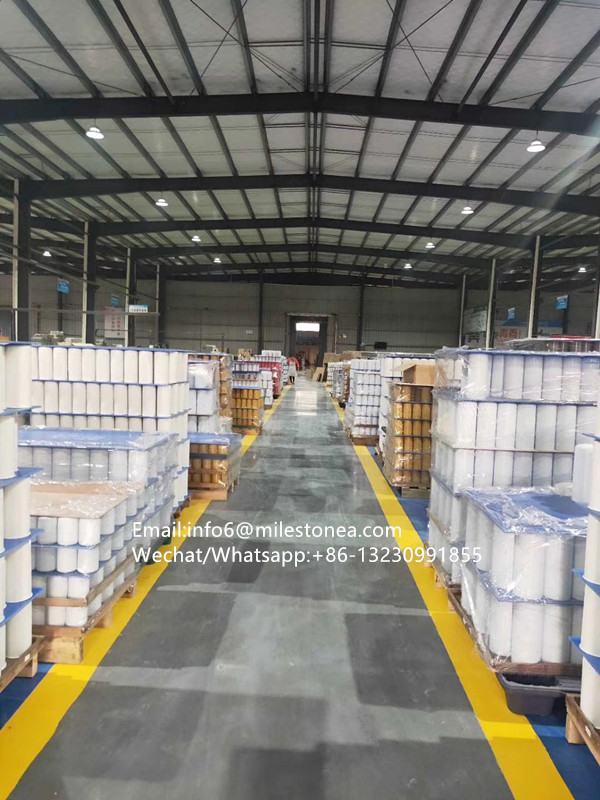

Product detail pictures:

_副本.jpg)

_副本.jpg)

_副本.jpg)

Related Product Guide:

All we do is usually affiliated with our tenet " Buyer to start with, Belief to start with, devoting about the food packaging and environmental defense for One of Hottest for Diesel Filter Assembly - Diesel Engine Fuel Water Separator Filter 1311812 FS19554 BF7672D RE62421 131-1812 For Truck Engine – MILESTONE , The product will supply to all over the world, such as: Armenia, Chile, America, What is good price? We provide customers with factory price. In the premise of good quality, efficiency must be paid attention to and maintain appropriate low and healthy profits. What is a fast delivery? We make the delivery according to customers' requirements. Although delivery time depends on the order quantity and the complexity of it, we still try to supply products in time. Sincerely hope we could have long term business relationship.

We have been looking for a professional and responsible supplier, and now we find it.