In the globalized business environment, the import of truck oil filters faces numerous challenges. Pain points such as high tariffs, low logistics efficiency, and unstable supplier quality constantly affect the operating costs and benefits of enterprises. How to optimize the supply chain has become the key to solving these problems and reducing import costs and logistics risks.

InSupply Chain Cost Analysis

Structure of Import Tariffs and Customs Clearance Fees

When importing truck oil filters, tariffs and customs clearance fees are important components of the cost. Sea freight is usually calculated based on the volume, weight of the goods, and the transportation distance. For example, transporting a standard container of oil filters from a major overseas production site to a Chinese port may cost several thousand US dollars. Although air freight is faster, it is much more expensive, often several times that of sea freight, and is generally suitable for emergency replenishment.

Inspection service fees may be incurred during the customs clearance process. When the customs inspects the goods, if the declared information of the goods does not match the actual situation or further inspection of the goods quality is required, additional fees will be generated. Demurrage is also a cost that cannot be ignored. After the goods arrive at the port of destination, if the goods cannot be picked up in time and exceed the specified free container use time, demurrage will be charged on a daily basis. The accumulation of these costs may have a significant impact on the import cost.

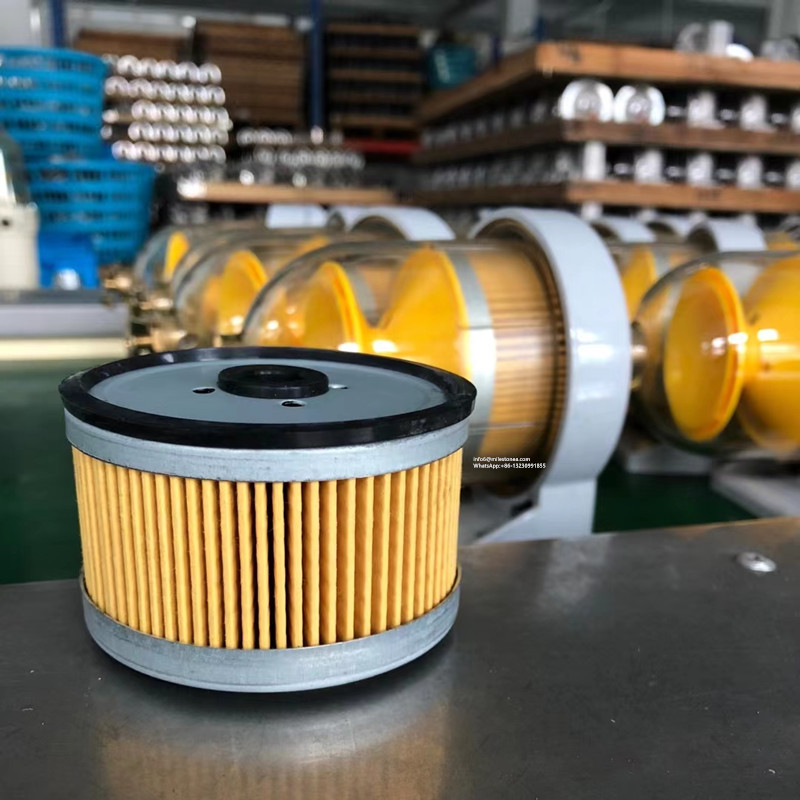

Case of the Price Advantage of Chinese Suppliers

As a major manufacturing country, China has demonstrated significant price advantages in the field of truck oil filters. Taking the suppliers on Alibaba as an example, the unit price of oil filters provided by some suppliers is as low as $0.3 per piece. Compared with some European and American suppliers, the price may be only a fraction of theirs. This benefits from China’s mature manufacturing industry chain, low labor costs, and economies of scale brought about by large-scale production. There are numerous factories producing truck oil filters in regions such as Hebei and Guangdong in China. These factories have strong production capabilities and can meet the demand for large-scale orders. Moreover, their product quality is constantly improving, and they have passed a series of international certifications, providing importers with more high-quality and affordable options.

Logistics Optimization Strategies

Precautions for Selecting Cost-effective Chinese Suppliers

When selecting cost-effective Chinese suppliers, importers need to pay attention to multiple aspects. First is the production capacity of the factory. For example, some factories in Hebei region have advanced production equipment and a large number of skilled workers, with a monthly production capacity of hundreds of thousands of pieces, ensuring stable supply. Second is the issue of qualifications. Many factories in Guangdong region have passed international certifications such as ISO 9001 Quality Management System Certification and TS16949 Automotive Industry Quality Management System Certification, which means they have strict standards and processes in product quality control. Importers also need to examine the delivery time of the factory to ensure that the goods can be delivered on time and avoid production stoppages or additional logistics costs caused by delays. At the same time, the after-sales service capabilities of the factory should also be understood so that problems with the products can be solved in a timely manner.

Cost Comparison and Application Scenarios of LCL and FCL Transportation

Less-than-container load (LCL) transportation is suitable for situations where the quantity of goods is small and not enough to fill a whole container. Its advantage lies in relatively low costs because the goods of multiple customers can be combined and transported in one container. However, the disadvantage is that the transportation time may be longer as it needs to wait for other goods to be assembled for container loading, and the customs clearance procedures at the port of destination are relatively complex, which may generate additional fees.

Full-container load (FCL) transportation is suitable for situations where the quantity of goods is large. Although the cost of FCL transportation is relatively high, the transportation time is more guaranteed, the safety of the goods during transportation is higher, and the customs clearance procedures are relatively simple. For example, for enterprises with strict requirements for delivery time, if the order quantity is large, choosing FCL transportation can better control logistics risks and ensure the timely arrival of goods. Importers need to comprehensively consider factors such as their own quantity of goods, delivery time requirements, and cost budget to choose between LCL and FCL transportation.

Risk Management Suggestions

Reducing Compliance Costs through “Paperless Customs Clearance” and Agreement Tariffs

“Paperless customs clearance” is a modern customs clearance mode that simplifies the traditional paper-based customs declaration process. Enterprises only need to declare to the customs through electronic data transmission, which greatly improves customs clearance efficiency. At the same time, it also reduces errors that may occur when manually filling out paper documents, reducing compliance costs such as fines caused by incorrect declarations.

In addition, using agreement tariffs is also an effective way to reduce costs. China has signed free trade agreements with multiple countries and regions, and imported goods that meet the requirements of the agreements can enjoy lower tariff rates. When importing truck oil filters, importers should carefully study the relevant agreements to ensure that the goods meet the conditions for enjoying the agreement tariff rates, thereby reducing tariff costs.

Case: A European Distributor Reduces Logistics Delays by Signing a Long-term Agreement with a Chinese Factory

A European distributor has long imported truck oil filters from China. In the past, due to the uncertainties in the logistics link, there were frequent delays in the arrival of goods, which had a significant impact on its business. Later, the distributor signed a long-term cooperation agreement with a Chinese factory. The agreement clearly defined the stable order quantity, delivery time, and logistics distribution method. The factory arranges production according to the agreement to ensure timely stockpiling. At the same time, both parties jointly negotiate with the logistics supplier to formulate a special logistics plan to prioritize the transportation of the distributor’s goods. Through this method, the European distributor has successfully reduced logistics delays, effectively controlled logistics risks, and also reduced operating costs.

Through in-depth analysis of supply chain costs, reasonable logistics optimization strategies, and the implementation of effective risk management suggestions, enterprises can reduce import costs, reduce logistics risks, and enhance their competitiveness in the market when importing truck oil filters.

Post time: Mar-13-2025