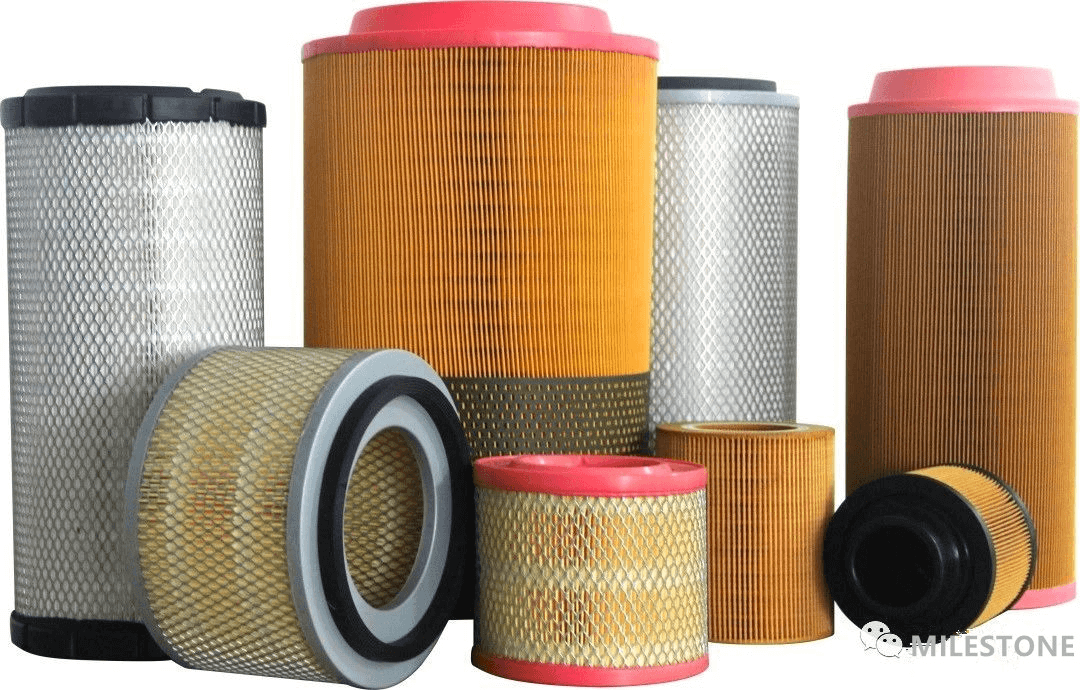

The air filter is an important part of the air compressor’s intake system, and is an assembly composed of one or several air filter elements. Its main function is to filter out harmful impurity particles that will enter the air compressor screw, ensure sufficient and clean air enters the air compressor, reduce the wear of the air compressor screw, bearing, cylinder liner, etc., and extend the service life of the equipment.

The importance of air filter to the entire air compressor system is self-evident, it is similar to the “mask” of an air compressor. But at present, the air filters on the market are uneven. How to distinguish the advantages and disadvantages of air filters?

This article lists the following key points of identification, I hope it will be helpful to everyone.

Judging from visual observation, high-quality air filters have the following characteristics:

1. The folding number is uniform, there is no obvious deformation, the folding height is relatively high, and the dust holding capacity is large;

2. The filter paper is smooth and has no obvious odor;

3. The rubber cover air filter in the high-quality air filter, the rubber cover is moderately soft and hard, and fits well during installation, is not easy to deform, and prevents dust from entering through the gap;

4. The iron cover air filter in the high-quality air filter has high processing precision and is installed in place.

From the perspective of technology-driven production:

1. Filter paper is the key part of the filter element. First of all, you must choose the appropriate filter paper: such as the air filter paper of the oil-injected screw machine, the air permeability of the filter paper of international brands such as MANN and DONALDSON is about 110-160, and many domestic ones choose about 500. Relatively speaking, the pressure difference is reduced, and it is not easy to fold, but the filtration efficiency cannot be guaranteed.

2. Choose a suitable polyurethane foam material: the end face has good flexibility and good resilience. With temperature changes, the stability is still very good, the compression is not large, and the size is precisely matched with the air filter assembly to prevent entry Air short circuit.

3. The origami process of air filter is one of the key links in the production of air filter, with regular intervals between each layer:

Prevent the filter paper from sticking and stacking-improve the dust holding capacity of the filter paper;

Stickiness of the filter paper-in a high humidity environment, the dust holding capacity of the filter paper will be greatly reduced;

Test result-increased service life: 50%.

The pros and cons of air filter are related to the application effect. From the perspective of daily application, the following common problems are solved:

1. The air filter and filter paper I use are not very good, but I often change it, can the same effect be achieved?

The same effect cannot be achieved. Bad filter paper has low filtration efficiency, and more dust particles will pass through the filter element and cause wear to the screw of the air compressor.

2. Is the longer the life of the air filter element, the better?

You cannot just use the length of life as a criterion for evaluating the quality of air filters. A good air filter should be a combination of high filtration efficiency and long service life. A good air filter manufacturer will comprehensively consider the performance indicators of air filters when designing and producing air filters.

3. Frequent maintenance of the air filter will improve the efficiency of the air filter?

On the contrary, over-maintenance will not only increase the maintenance cost, but also cause the risk of engine damage due to the following reasons:

Improper operation will damage the air filter;

Incorrect installation steps can easily cause dust to enter the air compressor;

The initial filtration efficiency of the air filter after each maintenance is low;

After each maintenance, the ash capacity of the air filter will drop by 30% to 40%.

to sum up

It is understandable that users purchase and replace equipment consumables to save maintenance costs, but not everyone can accurately determine product quality, which also provides opportunities for inferior products.

The majority of air compressor dealers can quickly identify and select high-quality air filters through the above points to ensure that sufficient and clean air enters the air compressor, greatly reducing the overall operating cost, avoiding shortened maintenance periods and machine damage.

Post time: Aug-10-2021