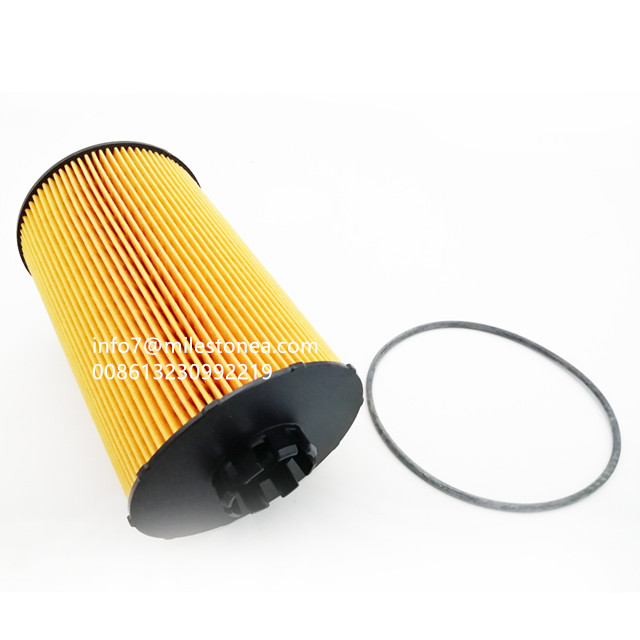

Hydraulic oil filter P170949 for truck oil filter

Hydraulic oil filter P170949 for truck oil filter

Quick details

Application:Hydraulic System

Material:Filter Paper

Color:Orange red

Filter material: high-quality Filter Paper

Car Model: skull

OE NO.:P170949

Type:Oil Filter

Model:P35AX

Car Fitment:Kalmar AC Lift

Year:2001-2005

OE NO.:P170949

Material:filter paper

Type:Cartridge filter

Size:Standard Size

Reference NO.:P170949

Truck Model:truck

Hydraulic filter element

The hydraulic filter element is used in the hydraulic system to filter out the particles and rubber impurities in the system to ensure the cleanliness of the hydraulic system.

1. It is divided into high pressure section, medium pressure section, oil return section and oil suction section.

2. It is divided into high, medium and low precision grades. 2-5um is high precision, 10-15um is medium precision, 15-25um is low precision.

3. In order to compress the dimensions of the finished filter element and increase the filter area, the filter layer is generally folded into a corrugated shape, and the pleated height of the hydraulic filter element is generally below 20mm.

4. The pressure difference of hydraulic filter element is generally 0.35-0.4MPa, but individual special filter elements are required to withstand high pressure difference, and the highest requirement is to withstand 32MPa, or even 42MPa equivalent to the system pressure.

Hydraulic filter element diagram

Hydraulic filter element diagram (9 photos)

5. The maximum withstand temperature, some require up to 135 ℃

The replacement time of the hydraulic filter element

Hydraulic excavators generally need to be replaced after 2000 hours of operation, otherwise the system will be polluted and cause system failure. According to statistics, about 90% of hydraulic system failures are caused by system pollution.

In addition to checking the color, viscosity, and smell of the oil, it is also necessary to check the oil pressure and air humidity. If you work in a higher altitude and lower temperature environment, you must also pay close attention to the carbon content, colloid (olefin) and sulfide in the engine oil, as well as the impurities, paraffin and moisture content in the diesel.

In special circumstances, if the machinery uses low-grade diesel oil (sulfur content in diesel oil is 0.5﹪~1.0﹪), the diesel filter and machine filter should be replaced every 150h; Machine filter. Use crushers, vibratory rammers and other equipment that have a heavy load on the hydraulic system. The replacement time of the hydraulic oil return filter, pilot filter and respirator filter is every 100h.

Contact us