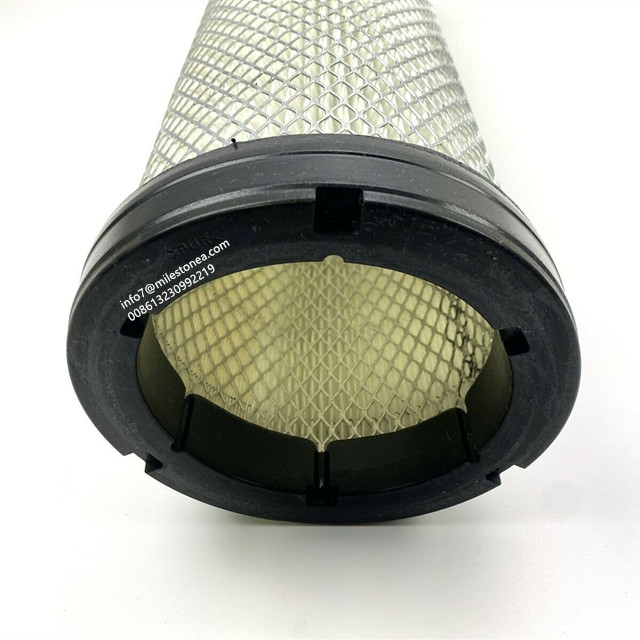

High Quality Air Filter AF25437 AF25523

| Manufacture | Milestone |

| OE Number | AF25523 |

| Filter type | Air filter |

| Dimensions | |

| Height (mm) | 501 |

| Outside diameter 2 (mm) | 142 |

| Maximum outer diameter (mm) | 151 |

| Inner diameter 1 (mm) | 109 |

| Weight & volume | |

| Weight (kg) | ~1.05 |

| Package quantity pcs | One |

| Package weight kg | ~1.05 |

| Package volume cubic Wheel Loader | ~0.013 |

Cross Reference

| Manufacture | Number |

| BALDWIN | RS3745 |

| DONALDSON | P537877 |

| DONALDSON | P777408 |

| DONALDSON | P777414 |

| DONALDSON | P778952 |

| DONALDSON | P782885 |

| DONALDSON | P838813 |

| John deer | AT175224 |

| John deer | F434395 |

| MAN | 8103040098 |

| MANN | CF15116 |

| MANN | CF151162 |

| VOLVO | 111100236 |

| VOLVO | 296251027 |

| VOLVO | 11110280 |

| VOLVO | VOE11110023 |

Introduction

Air filter element is a kind of filter, also called air filter cartridge, air filter, style and so on. Mainly used for air filtration in engineering locomotives, automobiles, agricultural locomotives, laboratories, aseptic operation rooms and various precision operation rooms.

The engine needs to suck in a lot of air during the working process. If the air is not filtered, the dust suspended in the air is sucked into the cylinder, which will accelerate the wear of the piston group and the cylinder. Larger particles entering between the piston and the cylinder will cause serious "cylinder pull" phenomenon, which is especially serious in a dry and sandy working environment. The air filter is installed in front of the carburetor or the intake pipe to filter out dust and sand particles in the air, ensuring sufficient and clean air to enter the cylinder.

Maintenance

1. The filter element is the core component of the filter. It is made of special materials and is a vulnerable part that requires special maintenance and maintenance;

2. After the filter has been working for a long time, the filter element in it has blocked a certain amount of impurities, which will cause an increase in pressure and a decrease in flow rate. At this time, it needs to be cleaned in time;

3. When cleaning, be careful not to deform or damage the filter element.

Generally, the service life of the filter element is different according to the different raw materials used, but as the use time increases, impurities in the water will block the filter element, so generally the PP filter element needs to be replaced in three months; the activated carbon filter element needs to be replaced in six months ; As the fiber filter element cannot be cleaned, it is generally placed on the back end of PP cotton and activated carbon, which is not easy to cause clogging; the ceramic filter element can usually be used for 9-12 months.

The filter paper in the equipment is also one of the key points. The filter paper in high-quality filter equipment usually uses superfine fiber paper filled with synthetic resin, which can effectively filter impurities and has a strong dirt storage capacity. According to relevant statistics, when a passenger car with an output power of 180 kilowatts travels 30,000 kilometers, the impurities filtered out by the filtering equipment are about 1.5 kg. In addition, the equipment also has great requirements for the strength of the filter paper. Due to the large flow of air, the strength of the filter paper can resist strong airflow, ensuring the efficiency of filtration and prolonging the service life of the equipment.