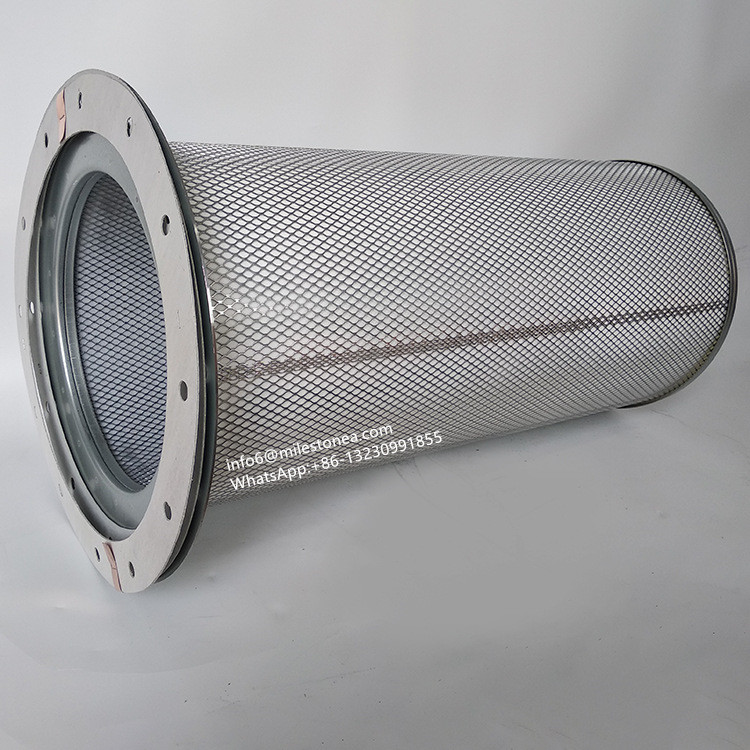

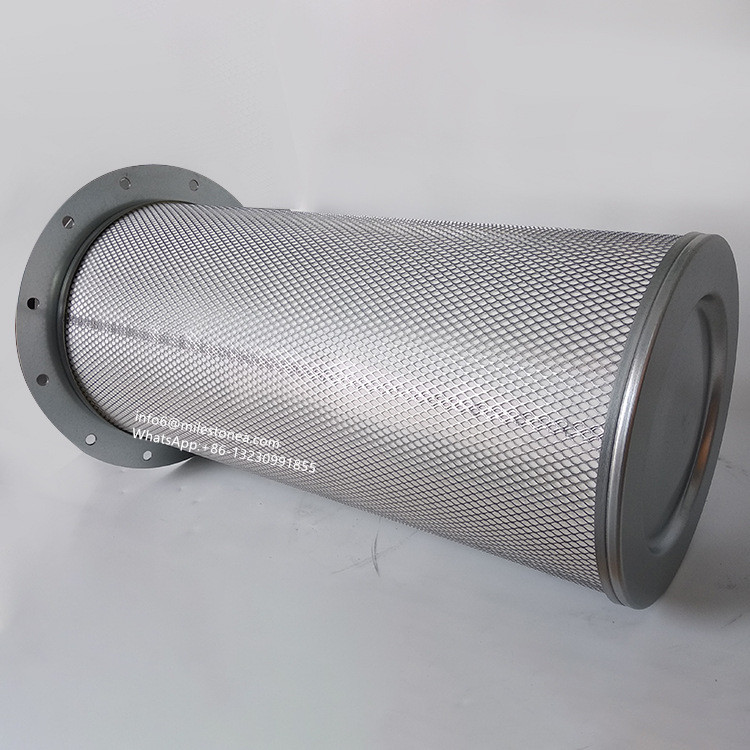

Factory supply screw air compressor 2205406518 compressor oil and gas separator filter glass fiber

Hazards of oil filter overtime use:

(3) Insufficient oil return after blockage leads to high exhaust temperature, shortening the service life of oil and oil separation core:

(4) Insufficient oil return after blockage, insufficient lubrication of the main engine, resulting in a serious shortening of the life of the main engine: after the filter element is damaged, the unfiltered oil containing a large amount of metal particles and impurities enters the main engine, causing damage to the main engine.

3. The role of the air filter element, the air filter element is an important protective barrier for the air compressor!

(1) Filter out the dust and impurities in the air inhaled by the air compressor. The cleaner the air inhaled, the more guaranteed the life of the oil filter element, oil and gas separation core and oil:

(2) Prevent other foreign objects from entering the host, because the components of the host are very precise. The important matching clearance is 30-150μ, so the entry of foreign objects will inevitably cause damage to the host, causing the host to “lock up” or even be scrapped.

Replacement standard of air filter:

The replacement standard of the air filter element is determined according to the service life of the air filter element and the ambient air quality of the air compressor. Therefore, the air filter element needs to be replaced in the following two situations:

(1) Replace it after the actual use time reaches the design life time. The designed service life of the air filter element is usually 2000 hours, and it should be replaced after expiration. If the actual air quality is better, it can be extended according to the actual condition of the filter element, but the maximum extended use time does not exceed 1000 hours. Air compressor environmental conditions are poor

Shorten usage time.

(2) It is designed to be replaced immediately after the blockage alarm within the service life period, and the set value of the air filter blockage alarm is generally -0.05bar.

Hazards of oil and gas separation core overtime use:

1. The separation efficiency is poor, resulting in high oil consumption and oil content in the compressed air, affecting the operation of the back-end purification equipment and the failure of the gas-consuming equipment to work normally:

2. Piezoresistance increases after blockage. As a result, the actual exhaust pressure of the unit increases, and the energy consumption of the unit increases:

3. After the failure, the glass fiber filter separation material falls off and enters the oil, resulting in shortened life of the oil filter element and abnormal wear of the main engine.

5. Special oil for air compressor (mineral oil semi-synthetic oil full synthetic oil)

Product Features:

(1) The county has excellent oxidation resistance and thermal stability.

(2) The county has excellent high temperature lubricity, reducing the wear of the air compressor.

(3) It has excellent heat dissipation effect and can effectively reduce the high temperature generated during the operation of the air compressor.

(4) The county has excellent rust resistance and sealing.

(5) It has excellent anti-emulsification properties.

(Exported company of Hebei Bossa Group CO., LTD)

Cell: 86-13230991855

Skype:info6@milestonea.com

Whatsapp: 008613230991855

https://mst-milestone.en.alibaba.com

Address: Xingtai High-tech Development Zone, Hebei . China