Diesel Engine Fuel Water Separator Filter 1311812 FS19554 BF7672D RE62421 131-1812 For Truck Engine

Product Size

Outer diameter: 83mm

Outer diameter 1: 69mm

Height: 154mm

Cross reference OEM NO

CATERPILLAR: 131-1812

BALDWIN: BF7672-D

DONALDSON: P550503

FLEETGUARD: FS19554

FLEETGUARD: FS19839

HENGST FILTER: H291WK

LUBERFINER: L 8681F

MANN-FILTER: WK 8110

PZL SEDZISZOW: PDS724

WIX FILTERS: 33638

Management and maintenance

Before using the fuel-water separator, the turbine operation and management personnel should understand the start-up, operation and maintenance requirements of the separator according to the product’s use and maintenance instructions.

一: Start-up inspection and preparation

1: Obtain the approval of the bridge before using the fuel-water separator equipment to discharge

2: Check the line installation of the fuel-water separator and whether the steering of the supporting pump is normal

3: Supply water to the oil-water separator and open the top air valve to allow air to escape

4: Check that there is no leakage on the water inlet and outlet systems of the fuel-water separator

2: Precautions during operation

1: Adjust the valve opening of the drain line to maintain pressure in the separator to facilitate the removal of dirty oil in the separator

2: Observe whether the pressure gauge, temperature gauge and other indicating instruments are normal

3: Observe the working conditions of the treated drainage water quality and oil concentration alarm

4: After the discharge is over, you should continue to inject clean water and run for 15 minutes to clean the separator

5: After stopping the pump, close the inlet and outlet valves to avoid the loss of clean water in the cylinder and reduce the oxidation and corrosion of the inner wall

6: Every time the oil-water separator is used to discharge, it should be recorded in the oil record book

Three: maintenance

1: Regularly clean the filter, open the release valve at the bottom of the separator, and remove the sediment and impurities deposited in the lower part

2: Clean the internal separation components of the separator in time, and do not use cleaning agents to clean the inner wall and components of the separator

3: When there is a failure, the cause should be found out and the failed coalescing element should be replaced in time

Four: internal anti-corrosion

Contact us

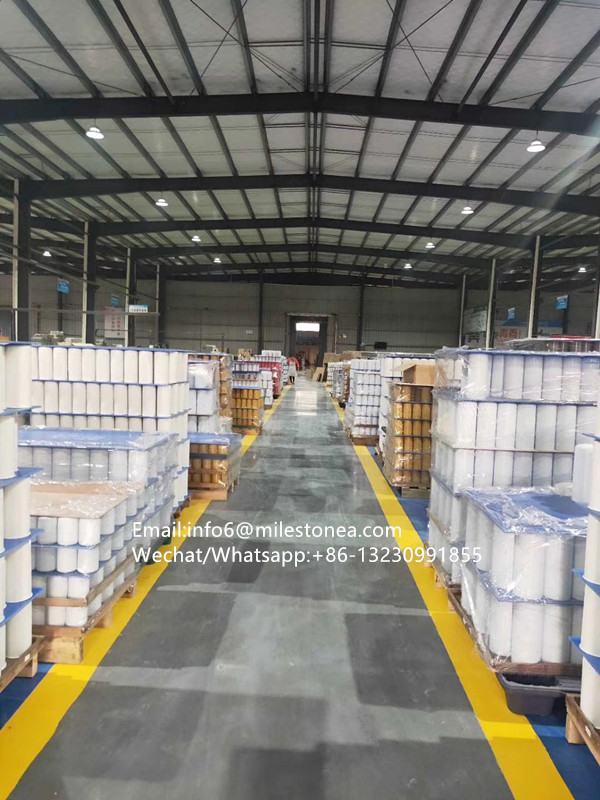

(Exported company of Hebei Bossa Group CO., LTD)

Cell: 86-13230991855

Skype:info6@milestonea.com

Whatsapp: 008613230991855

www.milestonea.com

Address: Xingtai High-tech Development Zone, Hebei . China

_副本.jpg)

_副本.jpg)

_副本.jpg)